Ungrounded delta secondary connected transformers were used extensively in the early era of industrial electrical distribution. Ability to operate machinery even in the presence of phase to ground short circuit condition was the main attraction of this connection. Delta connection however is prone to transient overvoltage due to capacitive coupling and arcing faults. Detection and clearing of ground fault is not possible using traditional overcurrent or ground fault protection devices in such connection.

To alleviate the concerns of using an ungrounded secondary distribution, someone invented a clever way to ground one corner of delta. Typically, the middle or ‘B’ phase is grounded, and the transformer thus connected is known as a corner grounded transformer. Corner grounded service is no longer popular for new installations and is being phased out with wye-grounded secondary service. There still exits a lot of legacy installations of corner grounded transformers.

Corner grounded system has the following advantages compared to delta connection:

- Stability of Phase-Neutral voltage. Ungrounded systems in general are subjected to transient overvoltage due to stray capacitance in the system. By intentionally grounding one phase, voltage with respect to ground is stabilized on other two phases.

- In a corner grounded system, phase-ground fault on any of the ungrounded phases (A or C) will cause large fault current and clearing by protective devices. In contrast, ground fault on a delta system will go unnoticed as there is no return path for ground current.

Read: What is ghost or phantom voltage?

Read: Voltage swell due to line-ground fault

Corner grounded system has the following disadvantages:

- Grounded phase (B) has to be identified throughout the facility distribution. This is to avoid accidental insertion of fuse or connecting meters, instruments, and relays in the grounded phase.

- Not capable of dual voltage service even though one phase is grounded. A 240V corner grounded system can only provide 240V single or three phase voltage.

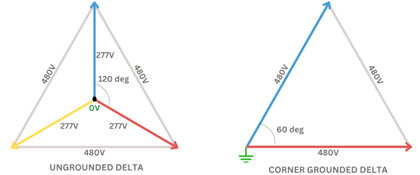

- Voltage with respect to ground will be higher than in a corresponding grounded system. A 480V corner grounded system will have 480V between phase A or C to ground. Compare this to a wye-grounded 480V system which will only have 277V between any phase to ground.

- Fault clearing for breakers is more severe than in solidly wye-grounded service as the breaker now has to clear ground faults at full phase-phase voltage. There is a risk of exceeding interrupting capability of marginally applied circuit breakers. Circuit breakers applied with corner grounded systems need to consider breaker’s individual pole interrupting capability.

- Lower cost slash-rated breakers such as 240/120V and 480/277V cannot be used.

- Certain grounding practice as discussed later in this article can cause flow of objectionable ground current. Ground current flow can lead to ground potential rise which may adversely affect performance of solid-state devices and may cause telephone interference issues.

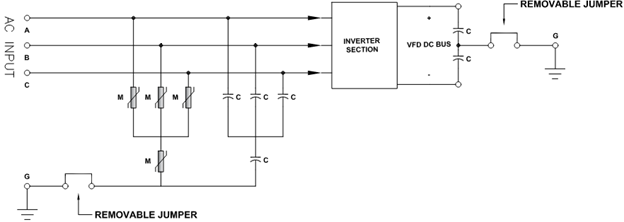

- Drives (VFD) typically have EMC filters (to meet requirements of IEC 61800-3) connected phase-ground. When VFD is applied with corner grounded transformer, their built-in EMI filter configuration has to be changed to phase-phase which is accomplished by removing a jumper. EMC filters are often rated for phase-ground voltage and application with corner grounded system applies full phase-phase voltage and can lead to misoperation or filter damage. Drive damage can result when corner grounded system experiences a ground fault and EMI filters are referenced to ground. If these precautions are taken VFD can work with corner grounded system.

Read: Transformer tap changer: How to select transformer taps?

Read: VFD input current vs output current

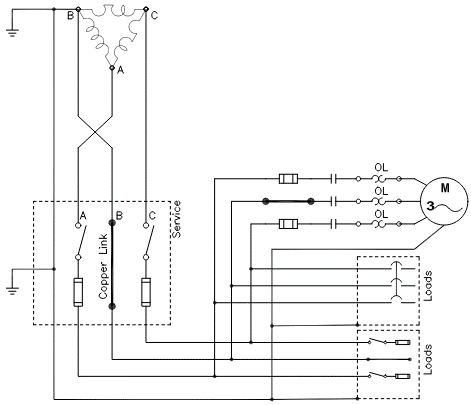

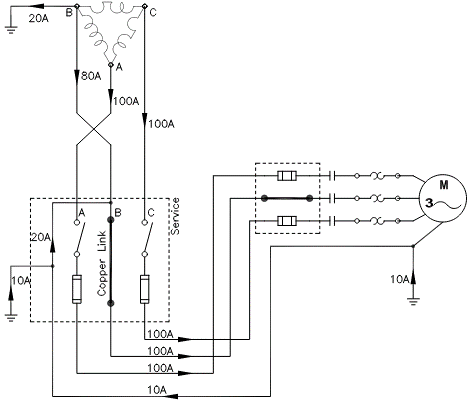

Typical corner grounded distribution is shown in figure 3. In this example, B phase is grounded at the transformer and not anywhere else. Utility provides four wires (three phases + ground). Another variation of this system is when utility only supplies three wires. See figure 6.

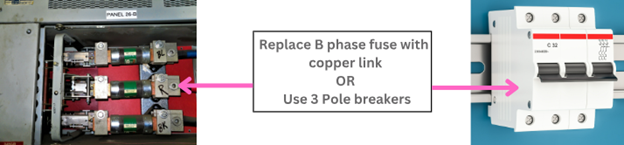

Notice that in figure 3, B phase fuse is not used and instead a solid copper link is inserted. This is done to prevent system from becoming ungrounded after a short circuit. Three pole circuit breakers that disconnect all three poles simultaneously can be used. Motor overloads are permitted on B phase though it can only be installed at the motor controller.

Read: Single point grounding in power systems

Identifying Corner Grounded Delta Connection

Any of the following measurements can be performed to identify if an installation is corner grounded delta:

- If the measured phase-ground voltage is equal to the system phase-phase voltage on phase A & C and voltage between B phase and ground is zero, then the system is corner grounded.

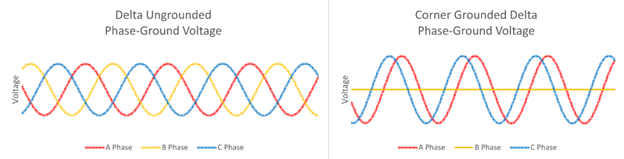

- Using an oscilloscope capture phase-ground voltage for all three phases. Phases A and C will indicate full phase-phase voltage while phase B will indicate zero volts.

- Oscilloscope or vector view of phase-ground voltage of phases A and C will indicate angle difference of just 60 degrees instead of usual 120 degrees.

Read: Wye and Delta connection vector diagram

Waveform comparison of ungrounded delta and corner grounded delta is shown in figure 1. Notice the ‘strange’ angle of 60 degree between phases A and C instead of usual 120 degrees. Note that if phase-phase voltage measurement were carried out on the corner grounded system you would see perfect 120-degree displacement. Only a phase-ground measurement will show 60-degree displacement. The reason for 60-degree displacement can be seen in the vector diagram below.

Read: Power quality check using multimeter

Protection Considerations for Corner Grounded Delta

No overcurrent device is permitted to be installed in the grounded phase (B phase typically) according to NEC 230.90 (B). For example, in a fused 3-phase switch, B phase fuse has to be replaced with a metal (copper) link to meet this rule. Metal link will restrict inserting fuse in to the grounded B phase circuit. If the overcurrent device disconnects all three poles simultaneously then three pole devices (3 pole breakers) are permitted.

Fuses are required on B phase when the application is to provide motor overload protection per NEC 430.36 or 430.37. In this case B phase fuse can be installed only at the motor controller and not at any service panel. Though motor overload protection only needs fuses on two phases that are not grounded, NEC table 430-37 states that for three-phase systems, three overloads are required.

When three pole breakers are connected to corner grounded system, it is preferred and recommended by many manufactures to connect the grounded B phase to the center pole of breaker.

Two pole breakers shall not be used for protecting three-phase circuit (remember B phase is grounded and hence breaker may be omitted) unless breaker is marked 1𝞍-3𝞍 to indicate suitability.

Slash-rated breakers can only be used if the lower voltage rating of breaker is greater than system voltage. For example, 240V/120V rated breaker cannot be used on a 240V corner grounded system.

Circuit breakers with straight-voltage ratings such as 240V or 480V are permitted to be used on corner grounded system as long as system phase-phase voltage is less than or equal to breaker voltage rating.

Read: Substation grounding: Role of crushed rock

Objectional Ground Current in Corner Grounded Delta Systems

Under a particular utility connection type where B phase is grounded at transformer and also at meter base or service entrance, there exists possibility for circulating objectionable ground current. This situation occurs when utility supplies just three wires from service transformer (Figure 6) and customer then grounds B phase at service entrance panel thus creating grounding conductor which is further extended inside the facility for equipotential bonding.

Read: Multipoint grounding in power systems

Part of B phase current from transformer now has two paths. One path is through normal phase conductor and other is through the parallel ground path. Parallel ground current can flow in any and all paths possible and the relative impedance of two paths determine current split. It is normal to see 10-20% of phase current on the ground circuit in such installations. If there are multiple corner grounded services, ground current can increase. Large ground currents can cause:

- Local and remote ground potential rise

- Enclosure currents in cabinets

- Misoperation of communication and ELV devices

If objectional ground current is noticed, the best solution is to ask utility to supply four wires (similar to figure 3). If this is not practical, then any method mentioned in NEC 250.6 for controlling objectional current may be attempted.

Read: Common impedance coupling in power systems

Ref 1: IEEE Green Book: IEEE Standard 142-1991

Ref 2: IEEE Blue Book: IEEE Standard 1015-2006