Ever wondered why crushed rock is spread over the surface of an electric substation? This article goes through the reasons behind this practice.

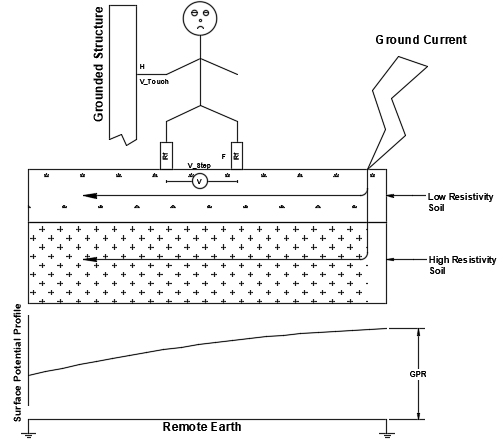

When current is injected in to substation ground during a fault, it tends to divide and flow depending on the resistivity of various soil layers. Flow of ground current over substation ground elevates its electric potential relative to distant grounding point assumed to be potential of remote earth. This is known as Ground Potential Rise (GPR) which is directly tied to two parameters: Step Voltage and Touch Voltage. Application of crushed rock is a means of controlling step voltage and touch voltage.

Step Voltage: During a fault condition, a person walking on the surface of substation can experience a voltage potential between his two feet (typically assumed to be 3.3ft or 1m apart). This causes a current to flow from one feet-through his body- to other feet. This voltage is known as step voltage or step potential. IEEE Std 80 defines step voltage as “The difference in surface potential experienced by a person bridging a distance of 1m with the feet without contacting any grounded object”.

Touch Voltage: The potential difference between the ground potential rise (GPR) and the surface potential at the point where a person is standing while at the same time having a hand in contact with a grounded structure [1]. Under a fault condition, surface potential of substation is raised relative to remote earth (0V). A person standing on the substation surface will also attain this elevated potential. When this person touches a perfectly grounded object (at 0V) a shock hazard exists. This voltage is known as touch voltage.

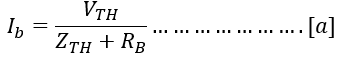

Body current when exposed to touch voltage is given by:

IEEE Std 80 defines the following conservative formulas for ZTH:

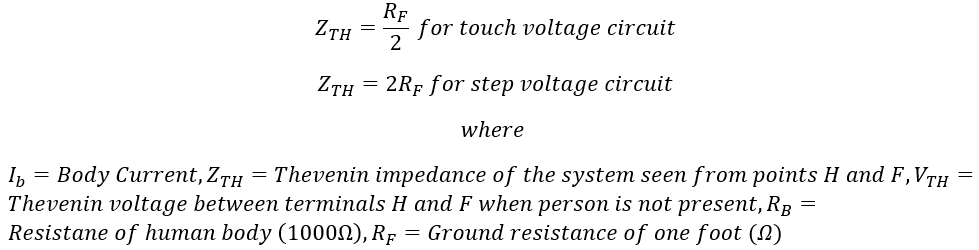

Looking at equation [a] the only parameter we can control is ZTH which is directly related to foot resistance RF. Anything we can do to increase RF will decrease body current Ib and hence improve personnel safety. It is here that crushed stone comes in to play.

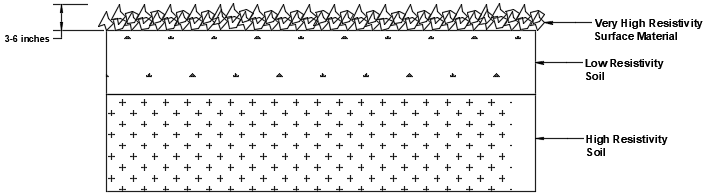

If we spread a thin layer of crushed stone (gravel) which typically has higher resistivity than most surface soil it will help increase contact resistance (RF) between surface soil and a person’s feet. Since the crushed stone has higher resistivity than surface soil, most of the ground current remains confined in the surface soil below the crushed stone. Since there is very little current in the layer with crushed rock, the surface voltage (step, touch potential) will be negligible. This is the basic idea behind using crushed rock in electric substations. A common surface material is the #57 crushed granite which has stones mostly in sizes from 3/4 inch to 1 inch is shown in the picture.

Another advantage of having a layer of crushed rock as surface material is that spacing of ground grid conductors (buried beneath the soil) can possibly be increased (saving copper) to meet the same step and touch voltage criteria. Surface materials also retard evaporation of moisture from the top soil layer.

Resistivity value of crushed rock depends on many factors such as type of locally available material, size of stone, washed vs un-washed stone (to remove fine material), moisture content, atmospheric contamination, type of water that can make the rocks wet (rain water vs sea water spray) etc. Rock resistivity needs be analyzed prior to application. Typical values of surface material resistivity of washed granite is 1.5*106Ω when dry and 5000Ω when wet. IEEE standard 80 provides typical resistivity values for different types of surface materials in different regions of United States.

Resistivity of surface soil and resistivity of surface material (crushed rock) needs to be evaluated prior to application. In most cases, surface soil resistivity will be lower than the crushed stone and everything will work as intended. But if opposite is the case then ground current will flow in the surface material layer and defeat the purpose. This ground current on the surface material layer will alter the surface potential substantially compared to the case without surface material. This is because the current now is confined to the small thickness of the surface material (crushed rock) instead of flowing through the entire cross section of top soil layer. Thus, any change to the surface material should not be done without taking in to account this possibility. Multi-layer soil analysis is recommended to evaluate resistivity of various soil layers.

Taking care of surface material layer: The layer of crushed rocks needs to be maintained periodically to avoid weed and plants from growing.

Weeds and plants growing in substation yard indicates that surface material (crushed rock) thickness is very less in that spot. This means step and touch potential in that area could be higher than originally designed. Care should be used when using commercial weed killing chemicals in substations as these chemicals can possibly corrode buried copper conductors.

Over time voids between rocks can become filled by fine soil beneath it or by excavations or by settlement of airborne dust. Additional layer of rocks may be added to mitigate natural settlement.

Summary:

By using high resistivity crushed rock in substations, exposure current to workers during fault conditions can be reduced.

Crushed rock is useful in reducing step and touch potentials.

Resistivity value of crushed rock depends on many factors such as type of locally available material, size of stone, washed vs un-washed stone etc.

Washed rocks have less dust and has more resistivity compared to un-washed ones. Removing dust also aids in faster drying time after a rain.

Resistivity of crushed rock is highly affected by the moisture content. Rock that is wet has lower resistivity and is less effective.

Among washed rocks, rocks with larger diameter typically has higher resistivity compared to smaller size counterparts. Practically rocks cannot be too large due to concerns with walking on the rocks and aesthetics.

Weeds if growing between rocks indicate the thickness of the surface material is reduced and needs additional layer.

Airborne dust, salt spray or other atmospheric contamination can degrade surface material effectiveness over time.

Care should be used while spraying weed killer in substation as chemicals may corrode the sub surface buried copper conductors.

[1] IEEE Std 80-2000; IEEE guide for safety in AC substation Grounding.