What is a recloser? Recloser is an automatic self-controlled and self-contained device used by electric utility companies to disconnect power when short circuit fault is detected on distribution lines. Recloser has current transformers, trip and closing mechanism in the same enclosure and hence is a self-contained unit. Relay for recloser is usually located on the pole below the recloser. Recloser is capable of multiple tripping and closing operations.

Main idea behind the use of recloser is that more than 90% of faults on overhead distribution lines are temporary and caused by tree branches, small animals, lightning strike, high winds etc. If recloser is able to trip and reclose again, fault may have disappeared (eg. dead animals) or forced to burn (eg. tree branch). If fault is not cleared, recloser will open the circuit and retry another close operation. These closing operations are commonly known as reclosing ‘shots’.

Reclosing allows for ‘fuse saving’ which means temporary faults will not result in downstream fuse operation.

What is fuse saving?

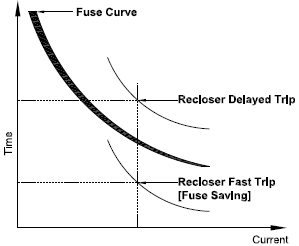

Fuse saving is a philosophy in which recloser trip curve is intentionally mis-coordinated with downstream fuses so that recloser operates faster and clears the fault. Downstream fuse is thus ‘saved’ from opening. Idea behind this is that majority of faults on overhead distribution circuits are temporary in nature and when recloser attempts another close, fault may have disappeared. By using recloser, utilities can avoid high cost of sending service technicians each time there is a temporary line fault. Downside of this method is that all customers on the feeder will experience momentary power interruption for all faults. Fuse saving practice is on a gradual decline within the industry.

Common recloser trip settings are 50, 70, 100, 140, 200, 280, 400, 560, 800, 1120, 1600A with voltage up to 38kV and interrupting rating up to 16kA. Recloser could be single or three pole. Some three phase reclosers have capability to sense current and trip and reclose individual phases. However, if recloser goes into lockout all three phases are locked out. Reclosers can be installed on poles or in substations and are available in vacuum or hydraulic controls. Vacuum units have the benefit of requiring less maintenance. Reclosers are defined by ANSI/IEEE C37.60.

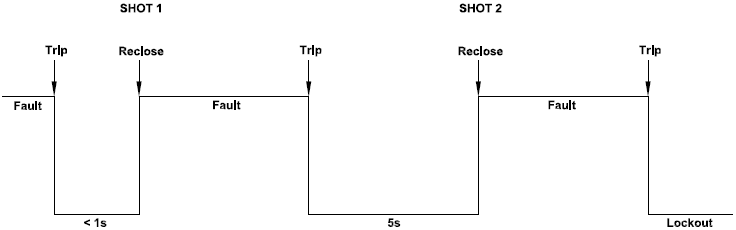

Common recloser operation is to have one fast trip operation, three delayed or two fast trip operation, two delayed.

Fast Trip: Fast operation is to clear temporary faults and allow fuse saving. For example, overhead line struck by lightning can result in flashover which can look like line fault to recloser relay. Conductor slapping due to high wind is another example. Since these faults are temporary, recloser will attempt to close back with no intentional delay.

Usually the first reclosing happens in less than 1s, typically within 10-30 cycles. Few cycles of delay is desired before reclosing the first time to allow ionized air from a fault or lightning strike to dissipate thereby reducing possibility of arc re-ignition.

Second reclosing attempt is in the range of 5-15s. Any dead birds or animals are likely to fall off the pole in this interval. Third attempt may be attempted around 45 seconds and so on. Most utilities only attempt two or three reclosing and rarely attempts fourth.

“80-90% of faults on overhead lines are temporary in nature.“

Considerations in deciding reclose time interval. Typical values are shown.

*De-ionization time (Lightning strike or due to other faults): ~ 10-20 cycles

*Reset time of any upstream electromechanical relays: ~ 0.1-1sec

*Additional time to account for animal related faults: ~ 5-15sec

*Customer specific situation

Note: Utility company engineers choose reclose timing based on specific situation. Time indicated here are typical examples only. Extremely long reclose time intervals have draw back if fault is due to broken and fallen conductors. Long reclose intervals may result in onlookers or first responders to be on the scene while reclosing occurs.

Delayed Trip: If fault cannot be cleared in first or second attempts, recloser switches to a delayed response allowing downstream fuses to clear the fault. If fault is not cleared, then fault can be assumed to be permanent and recloser will lockout. Line crew will have to be dispatched to locate and rectify the fault.

Read: Utility voltage tolerance

Reclosing on Feeders with underground cables

Some utilities employ reclosing on underground feeder cables and will likely do only one reclose attempt (1 shot). This is to prevent additional cable damage if that is the actual cause of fault. Though cable faults are permanent, reclosing will help restore power in the event fault is due to small animal (snakes, rodents etc) intrusion in switches, transformers etc.

Power Quality and Reclosing

Fast reclosing while quickly restores power has some power quality implications:

Voltage Sag on non-faulted buses: Multiple reclosing will result in repeated voltage sags on substation bus and all feeder loads connected to the bus. Depending on the short circuit strength of bus, this voltage sag can be ‘seen’ in a wide radius and can affect lot of customers.

Bus voltage decay: When recloser initially opens, motors in the system will start slowing down and can regenerate voltage on the bus. If voltage is restored before motors are significantly slowed down, then large torque pulsations on motor shaft can occur.

Cogeneration: When customer operates local cogeneration that ties into the utility grid, any recloser operation will have to be coordinated with the cogeneration disconnect time.

Automatic transfer schemes: It is a good idea to coordinate reclosing time to facility automatic transformer scheme so that unnecessary transfer to another source or generator can be avoided.

Equipment shutdown: When power is switched off and then back on, many processes can shut down (example chillers, conveyors etc.). This can be avoided to an extend if critical process computers and safety interlocks are UPS backed up or fed from a DC source. Some large drives have ‘flying restart’ capability when enabled allows drives to continue operating after a brief (few cycles) voltage loss

Ground Current Flow: When line fault is due to broken and fallen conductors, reclosing will lead to ground current flow and ground potential rise.

Read: Ground Potential Rise, Ferroresonant Transformer, VFD Undervoltage Fault