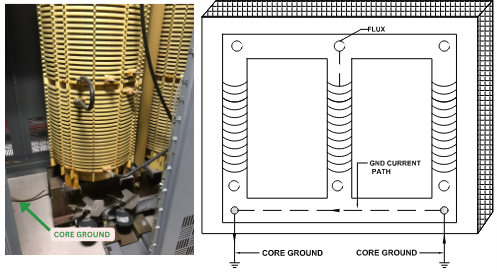

Laminated steel core of a power transformer is insulated from ground and is typically referenced to ground (earth) at a single location inside the transformer assembly. This single point grounding is done intentionally to avoid circulating current between core and ground that could lead to transformer overheating. Maintaining the integrity of core ground is very critical for ensuring transformer reliability. Accidental disconnection of core ground or accidental multipoint grounding of core could result in unsatisfactory outcomes which are discussed in this article.

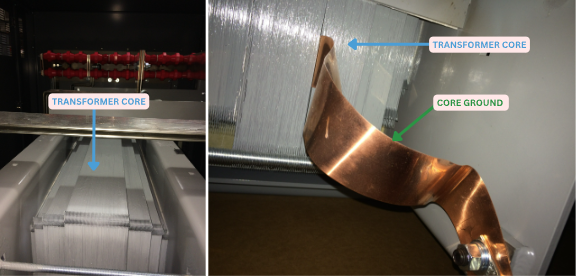

Power transformer can be constructed either in core or shell form. Transformer core is made of laminated sheet steel carefully stacked on top of each other. Sheet steel is separated from each other by a thin layer of varnish to keep them insulated from each other. Laminated and insulated steel sheets are used to prevent eddy current inside the core. Eddy currents can lead to excessive core heating and transformer damage.

Read: How to calculate reactive power of a transformer?

Read: Zero sequence impedance of core and shell type transformers

High voltage (HV) windings are wound on top of low voltage (LV) windings. LV windings are installed physically close to core. If core is left ungrounded, induced potential on laminated core can attain high voltage that may start arcing between core to ground. For this reason, core is grounded at one designated location for power transformers.

Though core needed to be grounded at one location, grounding at more than one location is not beneficial and often bring additional problems as discussed below.

Read: What is ghost or phantom voltage?

Transformer core-Drawbacks of multipoint grounding

Ideally, transformer core should be grounded at one location.

When core is accidentally grounded at another location, a closed electrical path is created through the core. Normal transformer time varying magnetic flux will create eddy current flow between core and ground. If this current magnitude is high, it can overheat the laminated sheet steel possibly leading to core damage.

Read: Types of transformer cooling

If core is connected at two locations and ground connections cannot be removed, a resistor may be inserted in series at one core-ground connection to limit eddy current flow and hence core heating. This resistor will have to be removed during dissipation factor (DF) test.

For small control transformers and small kVA transformers, manufactures may have the core connected to ground at multiple locations often unintentionally through core support nuts and bolts. Though this is not ideal the negative effects are insignificant for these small transformers.

Read: What is the difference between CPT and PT?

Transformer core-Drawbacks of losing core grounding

When factory installed core ground is removed intentionally or accidentally, core can attain voltage relative to grounded surface. Induced core voltage may lead to localized arcing to grounded surfaces that may not be immediately obvious until enough damage is done. In liquid filled transformers, these arcing can lead to the creation of hot metal gases, hydrogen (H2) and acetylene (C2H2) etc. When dissolved gas analysis (DGA) is performed and these hot metal gases are noticed, loose or missing core ground should be one of the suspects.

Read: How does power transformer saturate?

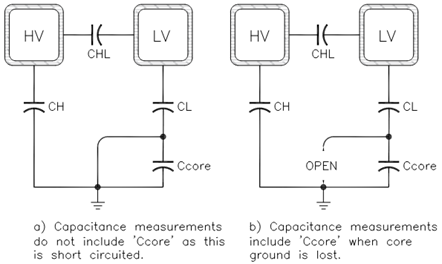

Another consequence of losing core ground is that it can negatively affect results of transformer testing- specifically power factor and capacitance tests. Under normal conditions, measurement of capacitance of the transformer will look like figure 4(a). Remember low voltage (LV) winding is wound closest to core. When the core ground is lost, capacitance value from low voltage winding (CL) will be low (capacitance of two capacitors in series will be less than either of the two capacitors), figure 4(b). Reduced capacitance of low voltage winding to ground may appear as a transformer defect and missing core ground should be a suspect in such situations.

Read: Parameters that determine transformer inrush current

How to determine health of transformer core ground?

For some very large power transformers, core ground terminal will be brought outside the tank where an intentional connection to ground can be made. For majority of industrial dry and liquid type transformers, core ground will be internal and can be only accessed after opening the tank. Accessing core ground for liquid filled transformer is especially difficult as the oil has to be drained completely.

Once core ground is identified, it needs to be temporarily disconnected and a DC insulation tester must be used to measure resistance between core and ground. Values greater than 200MΩ are acceptable while values less than 100MΩ are suspects indicating aging of core insulation supports. A very low value (~0Ω) often indicates that core is accidentally (multi) grounded at one or more locations.

On an operational basis, performing DGA, DFR tests and tracking the presence of hot metal gases in oil can provide good indication of developing core ground issues.

Read: Why are grounding transformers used?

Summary

Transformer core that is not grounded can attain voltage with respect to ground due to electromagnetic coupling with HV/LV windings. To prevent voltage buildup on core, core is intentionally grounded at one location from factory. If this core grounded is disconnected or if more than one core ground is installed, unintended consequences can result.

Grounding core at two or more locations can lead to following:

- A closed path for current is now created which can cause circulating eddy current between core and ground. If second ground cannot be removed, a suitably rated resistor may be inserted in to core-ground circuit to limit current.

- Core-ground current can cause core overheating and damage.

Read: Over temperature protection using RTD

Lack of core ground can lead to following:

- Core can attain voltage with respect to ground which may lead to micro arcs inside the tank. Arcing might go unnoticed until sufficient damage is done.

- Arcing between core and grounded surface in liquid filled transformers causes buildup of hot metal gases that can be identified during DGA tests.

- Normal transformer tests such as power factor and capacitance tests can indicate anomalous value since the lack of core ground decreases the LV winding to ground capacitance.