Triplex transformer is a three-phase transformer made of three single-phase transformers that are interconnected using bus to form three-phase bank. Single-phase units have individual core and coils. There is no magnetic connection between single-phase units, only electric bus or cable interconnection exist between individual units. Three separate transformers can be housed in one enclosure with all interconnections made inside the enclosure.

With YG-Y/YG-YG connection gaining popularity (since the connection prevents ferroresonance, provides ground source) in the electric utility world, triplex transformers are a requirement that many utilities ask for YG-Y/YG-YG winding connections. Triplex design avoids problem with tank heating that three core transformers have for YG-Y/YG-YG connections.

Read: Core vs shell Type Transformer

Advantages:

*Eliminates tank heating due to zero sequence flux in Y-Y connections.

*Can be used to serve large motor loads that are frequently started.

*Transformer can be disconnected down in to smaller single-phase units for transportation and installation in tight spaces. Since only cable/bus need to be reassembled the re-assembling process is not that troublesome.

Disadvantages:

*Larger overall foot print compared to similar size three phase three leg core type transformer.

*Limited by the maximum single-phase kVA that the manufacturer can build.

Tank Heating and Triplex Transformer

For a regular three leg-three core transformer, unbalanced line voltages or unbalanced load can create zero sequence voltage resulting in zero sequence flux in the core for YG-Y/YG-YG connections. Transformer connections with atleast one delta winding will not have this zero sequence flux issue.

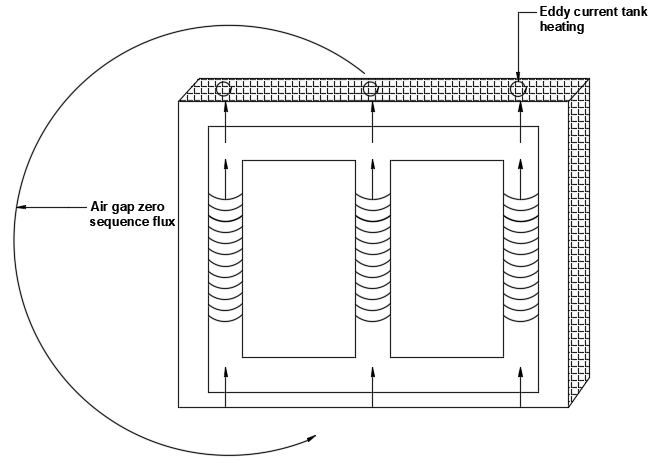

In three leg construction, there is no path for this flux to circulate within the core. The figure illustrates this problem. Remember that zero sequence flux has same magnitude and direction (angle) for all three phases. The flux reaches the top and finds that there is no return path to the bottom of the core. The only way for flux would be to jump the tank and air gap as shown.

Flux through the transformer tank (enclosure) creates localized eddy current heating. This localized heating on the tank can be enough to discolor/overheat transformer.

Three phase three leg Y-Y transformers are worst in this aspect. Shell type transformers do not have this problem. If the transformer has at least one delta winding zero-sequence flux will circulate inside the close delta and no zero-sequence flux heating can happen irrespective of the core construction.

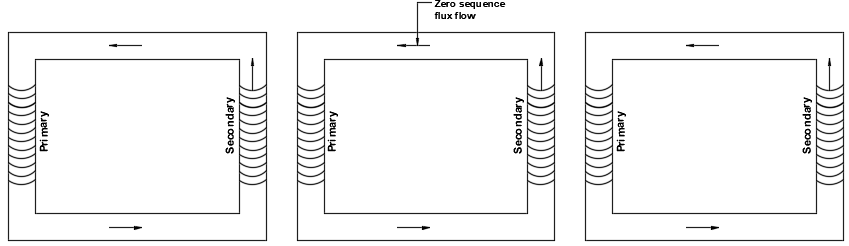

How to eliminate tank heating? To eliminate tank heating, do not use core type 3 leg transformer in Y-Y configuration. A better approach will be to use a 4 or 5 leg core type or shell type transformer to minimize the risk of tank heating. To completely eliminate the risk, either three single phase transformers has to be used or use triplex construction. Since triplex construction has three separate core/coil assemblies the zero-sequence flux can circulate as shown below in the individual core/coil and will not cause tank heating.

If triplex transformer is not desired for Y-Y application and installing 3 no.s single-phase transformers, 4/5 leg core or shell transformer is not an option, alternative will be to use three core three leg transformer with primary protective devices that sense loss of voltage magnitude and unbalance. If voltage unbalance is detected, all primary phases need to be disconnected simultaneously. Secondary side unbalance detection may also be installed along with primary side detection. Minimum requirement will be to have unbalance detection on the primary.

By doing this a potential unbalance condition can be detected and transformer tank heating due to zero sequence flux can be avoided.