Grounding or earthing of equipment containing high frequency noise sources require that connection be done with a low impedance path. At high frequencies it is the inductive impedance of the circuit that is of importance rather than DC resistance of conductor. Since inductance is directly proportional to length, minimizing length is a suggested good practice but practical conditions dictate the length. There are two common types of ground conductors for grounding: Round conductor ground wire and Flat ground strap. Which one of these provide low impedance for high frequency ground current?

Ground Wire

Round conductor ground wire is the most common method for grounding enclosures and circuits at power system frequency (50/60Hz). At higher frequencies round ground wire may not the best choice for achieving low impedance.

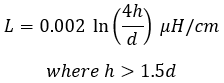

Inductance of a round conductor is inversely proportional to log of conductor diameter. For a single round conductor with diameter ‘d’ located at a height ‘h’ above current return plane, the loop inductance is given by:

Increasing diameter of round conductor ground wire does not reduce inductance significantly due to the logarithmic relationship between diameter and inductance. Doubling the diameter will only reduce inductance by 20%. Size needs to be increased by 1,200% for a 50% decrease in inductance. For these reasons it is difficult to achieve lower inductance (and hence impedance) for high frequency applications when using round conductor ground wire.

Ground Straps

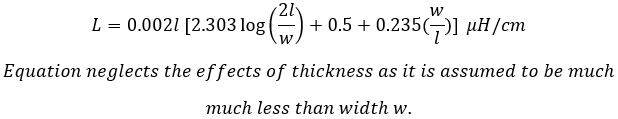

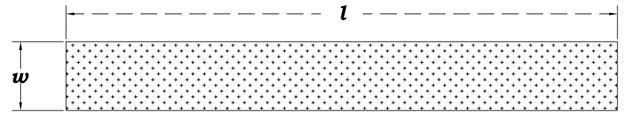

Inductance of flat rectangular ground strap is given by:

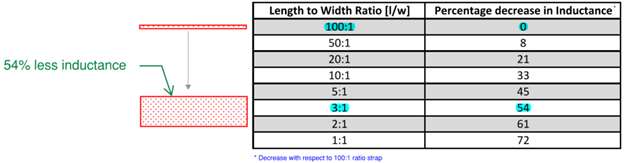

Length to width ratio of a flat ground strap has significant influence on the inductance of strap. Inductance (and hence impedance) decreases as the width is increased for a given length.

Table below lists the percentage decrease in inductance as a function of length to width (l/w) ratio for a fixed length rectangular cross section conductor [Ref 1].

Inductance of a flat ground strap of given length will decrease as the length to width ratio is decreased, meaning the length remains same while width ‘w’ is increased. Obviously from the equation for inductance for flat strap inductance will increase with strap length. For achieving lower net inductance, the following need to happen:

- Shortest strap length for the application

- Strap with smallest length-to-width ratio (l/W)

Recommended practice is to install short length ground straps with length-to-width ratio of 3:1 or less. Equipment enclosure should be bonded to ground reference plane at multiple locations, preferably at four corners of enclosure to reduce net inductance further. Inductance of two ground straps in parallel will be half the inductance of one strap, provided they are separated so that mutual inductance is negligible. Ground straps can be made of solid metal or braid with braid giving more flexibility. Copper braid should be tinned, or silver plated to prevent corrosion. A tinned or plated braid should perform as well as a solid strap.

Summary

- Grounding of equipment with high frequency noise sources require low inductance ground leads.

- There are two common ground leads: Round ground wire and Flat ground strap.

- Lead length of ground wire or ground strap directly increases the inductance and hence should be kept to minimum.

- Increasing diameter of round conductor ground wire does not reduce inductance significantly.

- Ground wire is adequate for power frequency applications while flat ground straps perform better at higher frequencies.

- Inductance of flat ground strap decreases as length-to-width ratio is decreased.

- Recommended length-to-width ratio for ground straps is 3:1 or less.

- Install multiple ground straps at each corner of the equipment to lower the inductance further.

Reference 1: Electromagnetic Compatibility Engineering, Henry W Ott, Wiley

Read: High impedance in earth ground wire due to magnetic field