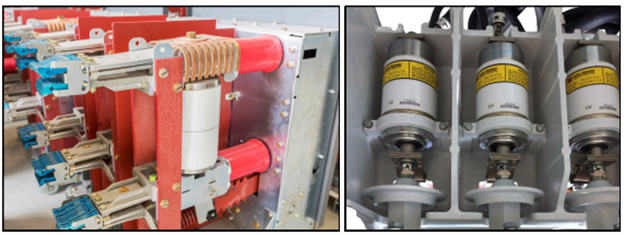

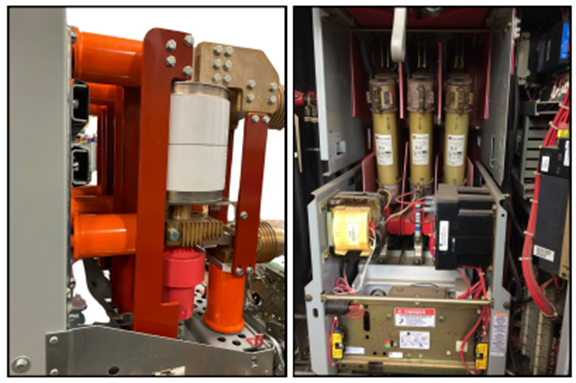

Vacuum Circuit Breakers (VCB) and Vacuum contactors (VC) uses the insulation properties of vacuum to perform current interruption. Both VCB and VC can be used to switch medium voltage circuits that power motors, transformers etc. For a given application, it may be confusing to decide whether to use vacuum breakers or vacuum contactors. Are there any advantages/disadvantages of using one over the other? In this article we will explore some of the similarities and key differences in the application of VCB vs VC.

Both Vacuum breakers (VCB) and Vacuum contactors (VC) interrupt electric current and resulting arc in a sealed vacuum bottle. Main function of VCB and VC is to make and break electric circuit (typically at voltages above 1kV) between source and load. One side of the vacuum bottle is fixed, and other side is movable. VC has very high mechanical endurance of compared to VCB. VC also has higher electrical endurance compared to VCB when interrupting rated load current.

Typical application of VC is for switching medium voltage motors, small transformers, capacitor banks often repeatedly as part of process control whereas VCB is used to switch large transformers, large motors, feeder circuits infrequently. Vacuum contactors have limited short circuit interrupting capability (5kA-14kA) unlike vacuum breakers that has high (40kA-63kA) interrupting capability. Per standards, VC should be capable of switching ten times rated current (ANSI) or eight times (IEC). This means a 400A VC should be capable of opening current up to 4000A (ANSI) or 3200A (IEC). Limited short circuit interrupting capacity is one of the main difference between VCB and VC.

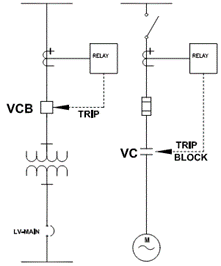

Overcurrent and short circuit protection in a VC circuit is often accomplished using a combination of two devices namely- Overload relay and Current Limiting (HRC) fuse for UL class E2 controllers. Over load relay opens the VC for load switching and normal overloads whereas CL fuse will operate for short circuit current above the rating of VC. Two devices are needed since the short circuit interrupting capability of VC is low unlike VCB.

Read: Auto recloser and power quality

Overcurrent and short circuit protection in a VCB circuit is accomplished using Overcurrent relay. VCB is capable for breaking the load current as well as the short circuit current unlike VC.

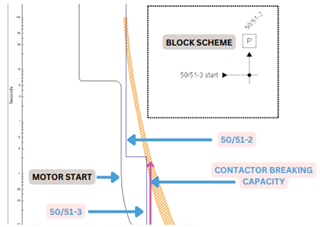

Protection relay settings used in VC circuits need to be carefully set so as to NOT open VC for fault current greater than the rated interrupting capability of contactor. Typically, the electronic over load relay protects up to the locked rotor current of motor and fuse protects for short circuit faults. Overload relay should be programmed to block the protection settings if the measured current is greater than the interrupting capacity of VC. VC remains closed for fault current above its interrupting capacity. Same considerations apply if VC is used to switch transformers. In figure 3, 50/51-3 is set for current slightly less than the interrupting capacity of contactor. If fault current is above 50/51-3 setting, then the relay will block the 50/51-2 element from opening the contactor and let the fuse interrupt this fault current. Serious contactor damage can result if VC is forced to open higher than rated short circuit current. MV power fuses and contactor need to be carefully coordinated and this is often done by MCC manufacturer based on load characteristics. VCB do not have these restrictions as long as the breaker is rated based on available short circuit capacity of the circuit.

Read: How to identify capacitor switching transients?

VC uses contact materials that result in lower current chop level of ~1A. Lower current chop level is important in minimizing voltage transients caused due to current interruption in vacuum. VCB has higher chop current of ~5A resulting in higher voltage transients. For this reason, transformers and motors fed by VCB may be required to have snubber or surge capacitors installed. Surge capacitors may be used in protecting expensive motors irrespective of being switched by VC or VCB.

VC used for motor control is almost always electrically latched meaning a loss of control voltage will lead to VC opening. Mechanically latched contactors require a ‘trip’ or ‘open’ signal to open the contactor. Mechanically latched VC’s are available but are usually limited to application with small transformers and feeder circuits. Mechanically latched VC’s are typically not used in motor control due to the risk of accidental motor re-starting following power loss though it is permitted if sufficient protection such as undervoltage tripping is enabled.

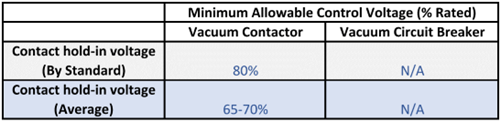

As shown in figure 6, electrically latched, or electrically held vacuum contactors are susceptible to contact drop off if control voltage sags below 80%.

Control power derived from source side control power transformer is susceptible to voltage sags. Stable control power is critical for reliable VC performance. A Ferroresonant constant voltage transformer may be considered in this situation to stabilize control voltage. Unlike VC, control voltage sag do not result in VCB opening as they are mechanically latched and will need an actual ‘trip’ command to open.

Important characteristics of vacuum contactors and vacuum breakers are summarized below.

| Characteristics | Vacuum Circuit Breaker [VCB] | Vacuum Contactor [VC] |

|---|---|---|

| Switching | In-frequent switching applications | Frequent switching applications |

| Continuous Current | High switching current capability (~ 4,000A) | Low switching current capability (~ 630A max) |

| Typical use | Transformers, Capacitors, Feeders, Large Motors | Motor control, Small transformers, Capacitor bank |

| Size & Weight | Larger physical size and weight compared to VC | Smaller physical size and weight compared to VCB |

| Endurance | Mechanical endurance: High ~5,000 – 10,000 mechanical operations | Mechanical endurance: Very high ~ 2.5 million operations |

| Endurance | Electrical endurance: High ~10,000 operations at rated current | Electrical endurance: Very high ~400,000 operations at rated current |

| Fault Interruption | High fault interrupting capacity (~40kA-63kA) | Low fault interrupting capacity (~5kA-14kA) |

| Fault Interruption | Fault protection accomplished using overcurrent relay | Fault protection using overcurrent relay and CL HRC fuse working together |

| Fault Let Through | Fault let through current can be higher in VCB (3-5 cycle breaker operation) | Fault let through current is less due to CL HRC fuse (1/4 cycle fuse opens) |

| Control Scheme | Mechanically latched: VCB remains closed on control voltage loss | Electrically held: VC opens on loosing control voltage. Latched contactors available |

| Maintenance | Require higher maintenance than VC | Low maintenance |

| Transients | Contact materials used in VCB has higher chop current of ~5A | VC has low chop current of ~1A. Less prone to creating transients than VCB |

| Service | Time to return to service after short circuit and VCB opening is very less compared to VC | Time to return to service after short circuit and fuse clearing is long compared to VCB |

| Cost | High | Moderate |

| Drawout Capability | Fixed and Drawout VCB available | Fixed and Drawout VC available |

| Remote Operation | Suited | Suited |

| Local Operation | Electrical or Manual | Electrical only. Manual options available. |

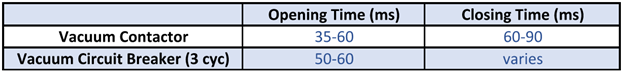

| Opening Speed (ms) | 50-60 (3 cycle breaker) | 35-60 |

| Closing Speed (ms) | Varies | 60-90 |

Read: Autotransformer starter: A reduced voltage motor starting method