SEMI F47

SEMI F47-0706 is the specification for Semiconductor Processing Equipment voltage sag immunity originally published in year 2000 and updated in 2006. The standard has been implemented by essentially all semiconductor fabs and has been a huge cost saver for the industry. Semiconductor wafer production is very sensitive to voltage sag (voltage dip) events and one voltage sag event could cost facility hundreds of thousands of dollars per voltage sag.

Voltage Sag

SEMI F47 sets out limits of voltage sag that the equipment needs to tolerate without creating any process upsets or shutdowns. SEMI F47 suggests that semiconductor manufacturers may use this standard in their specification whenever they purchase equipment. By doing so the manufacturer can make sure all the equipment used for semiconductor production has been tested and certified to SEMI F47 standard. Compared to other voltage sag immunity curves (CBEMA, ITIC), SEMI F47 standard is more stringent on the tolerance limits.

SEMI F47 does not address product quality and the purpose of the standard is to keep the equipment running without any operator intervention when exposed to voltage sags above the tolerance curve.

SEMI F47 – 0706 references IEC standard (IEC 61000-4-34) for test protocol information.

SEMI F47 Requirements

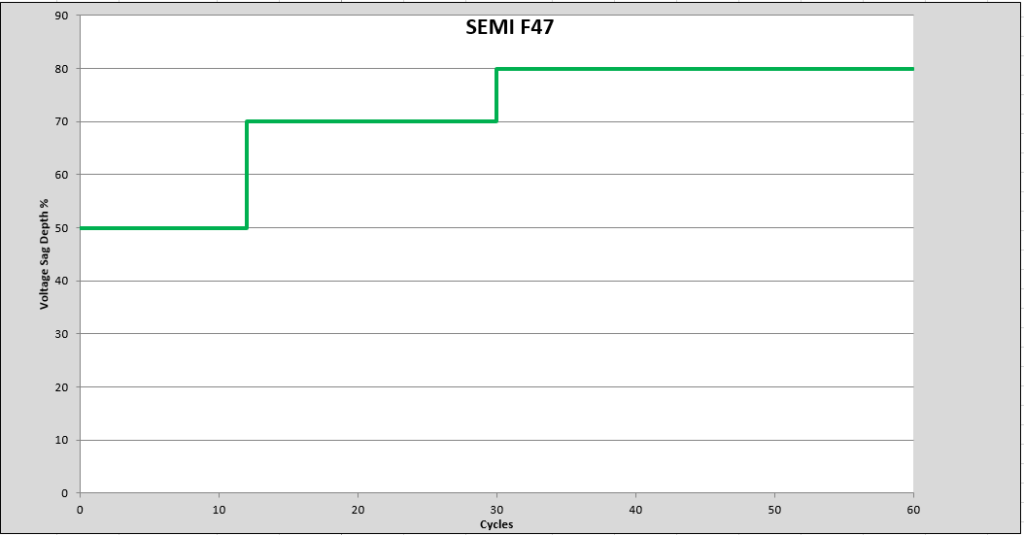

SEMI F47 curve

SEMI F47 standard requires that the tested device successfully ride through voltage sag with magnitude up to 50% of nominal voltage for up to 12cycles at 60Hz. Most of the power grid voltage sags are in the 3-10 cycle range. This means that having a SEMI F47 compliant system enables successful ride through of most utility generated voltage sags.

SEMI F47 Focus

The primary focus of the specification is semiconductor processing equipment such as Etch, film deposition, photolithography equipment etc. The secondary focus of the specification is subsystems and components that aid in the semiconductor manufacturing process. Some of these are:

- Power supplies

- Computers

- Robots

- AC Contactor

- AC Relays

- Chillers

- Adjustable Speed Drives etc.

As can be seen from the list above the secondary focus covers many equipment that could be present in any other modern industrial facility not necessarily related to semiconductor manufacturing. Some industries not in the semiconductor field tend to look at SEMI F47 and try to make their most critical process SEMI F47 compliant.

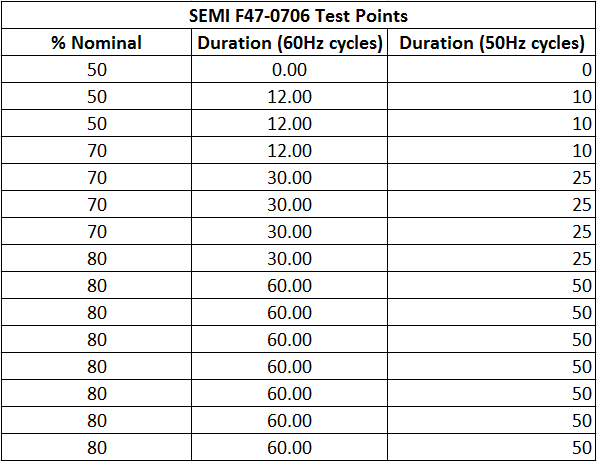

SEMI F47 test points:

The following test points can be used to create a graph like the one shown above in Microsoft excel.

SEMI F47 Test Points

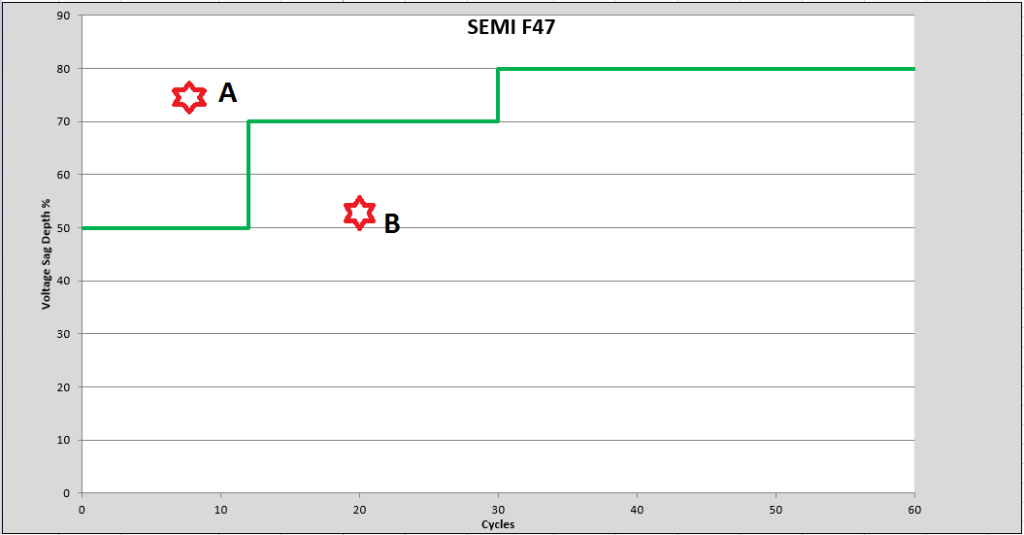

Voltage sags above the SEMI F47 curve (point A) should not cause process interruption or equipment shutdown for an equipment that complies with this standard. Voltage sags below the SEMI F47 curve (point B) may cause process interruption.

There are additional requirements to SEMI F47 which are not part of the standard. These are the requirements to tolerate sags to 0% for 1 cycle, sags to 80% for 10 seconds and continuous sags to 90%.

Terminology

Voltage Sag Immunity: The ability of equipment to withstand momentary electric power interruptions or sags [IEEE 1250].

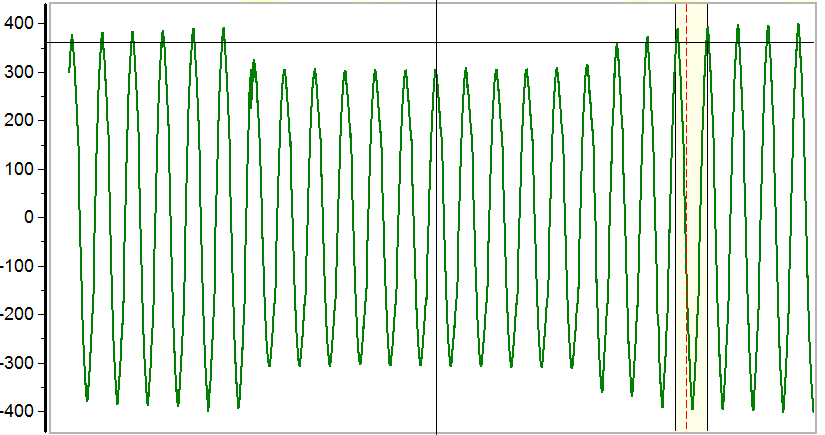

Voltage Sag: An RMS reduction in the ac voltage, at the power frequency, for duration from half cycle to few seconds [IEEE 1100]. The IEC terminology for this phenomenon is voltage dip. Voltage sags are most often caused by faults on the utility system although they may be caused by faults within the facility or by large motor starts. IEEE standard 1159 defines voltage sag as a decrease in RMS voltage at the power frequency for duration from 0.5 cycle to 1 minute, reported as the remaining voltage. Typical values are between 10% to 90% of voltage.

Other Voltage Ride Through Standards

ITIC curve is published by Information Technology Industry Council (ITIC) formerly known as Computer & Business Equipment Manufacturer’s Association (CBEMA). This curve provides an AC voltage boundary that most information technology equipment (ITE) can tolerate without experiencing unexpected shutdowns or malfunctions. Information technology equipment could include single phase computers, printers, scanners etc. The CBEMA curve is a precursor to ITIC curve and was published in the 1970’s.