Power transformers can have different kVA depending on the type of cooling method used. Heat is one of the main limiting factors in transformer design. Any method that extracts heat from the transformer can result in increased transformer capacity. Each transformer cooling class increase kVA capacity by 25% – 50% depending on the type and size of transformer. Transformer cooling classification is different for dry type and liquid (oil) filled transformers.

Cooling classes found on dry type transformer name plate is designated as below:

AA: Ventilated self-cooled

AFA: Ventilated forced air-cooled

AA/FA: Ventilated self-cooled/forced air cooled

ANV: Nonventilated self-cooled

GA: Sealed self-cooled

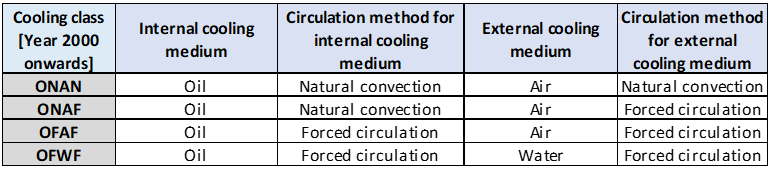

Cooling classes found on liquid filled transformer name plate is designated as below:

First letter-Indicates internal cooling medium in contact with windings

O mineral oil or synthetic insulating liquid with fire point of 3000C

K Insulating liquid with fire point > 3000C

L Insulating liquid with no measurable fire point

Second letter-Circulating method for internal cooling medium

N Natural convection

F Forced circulation

D Forced circulation with directed cooling in to atleast main winding

Third letter-External cooling medium

A Air

W Water

Fourth letter- Circulating method for external cooling medium

N Natural convection

F Forced circulation

Using the above information, common types of transformer cooling for oil filled transformers can be listed as below:

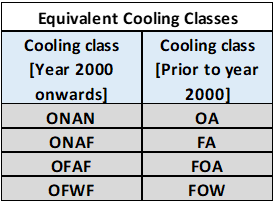

Prior to year 2000, transformer cooling class designations were little different. In year 2000 ANSI ratings were made consistent with IEC designations. New method uses a four-letter code that indicates the cooling method (IEEE C57.12.00-2000). Comparison of old and new cooling classes is shown on the left. As an example, old classification of OA/FA/FOA is equivalent to new classification ONAN/ONAF/OFAF.

From the table above it can be seen that an ONAN transformer uses oil as the internal cooling medium with natural air convection and air as external cooling medium with natural convection. Similarly, ONAF transformer uses oil as the internal cooling medium with natural air convection and air as external cooling medium with forced circulation (uses fans on the cooling fins).

Similar designation can be made for KNAN transformer too.

Read: What is KNAN/KNAF Transformer?

![Dry Type Transformer: Class AA Cooling [Left] and AA/FA Cooling [Right]](https://voltage-disturbance.com/wp-content/uploads/2020/10/Dry-Type-Transformer-Class-AA-Cooling-and-AA-FA-Cooling.png)

![Oil Filled Transformer, Cooling Class ONAN [Left] and ONAF [Right]](https://voltage-disturbance.com/wp-content/uploads/2020/10/Oil-Filled-Transformer-Cooling-Class-ONAN-Left-and-ONAF-Right.png)

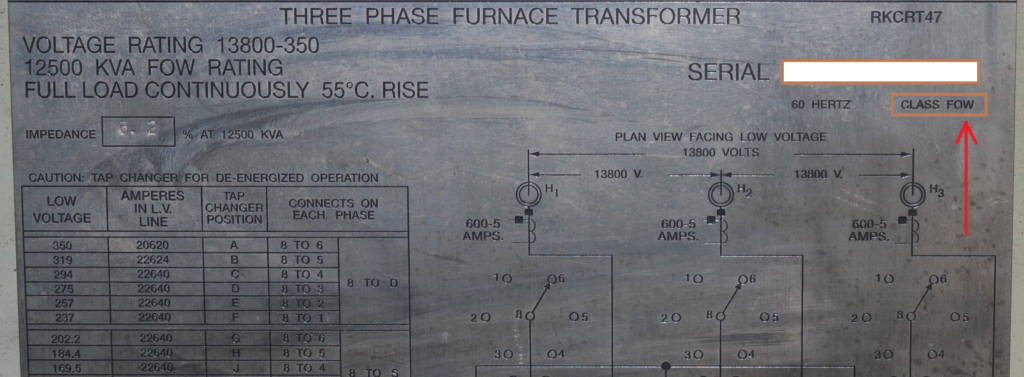

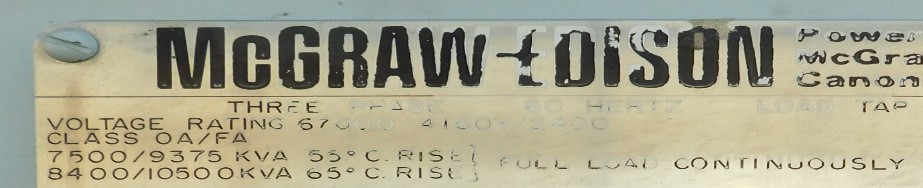

Transformer Capacity Increase with Cooling. With each cooling method, kVA rating of transformer increases typically by one third (33%) but can vary between 25-50% depending on the type and size of transformer. One example is shown below. Transformer below uses old cooling classification OA/FA and kVA is also listed below.

Name plate states that base kVA of the unit is 7,500kVA with OA cooling and 9,375kVA with FA cooling, both with 550 C temperature rise. If a higher temperature of 650 C can be tolerated then transformer capacity is increased to 8,400kVA/10,500kVA with same OA/FA cooling.

Referring to previous picture of ‘FOW’ class transformer nameplate, base kVA of 12,500 requires ‘FOW’ (Forced Oil and Water). This transformer requires water cooling to function. The name plate or transformer data sheet will also suggest the required water flow (gallons/min) and the inlet water temperature. This illustrates the importance of reviewing the transformer kVA and ascertaining under what cooling method that kVA is attained. Lack of engineering review on cooling methods for critical and higher current power transformers can lead to premature transformer failure.