LED Lamps

There has been a recent uptrend in the sale and usage of Light Emitting Diode (LED) based lighting for Industrial, Commercial and residential applications. This has led some concerns in the industry about the negative effects caused by the large scale introduction of LED lights in to the power system. On the other hand LED lights offer enormous benefit in the areas of power consumption and long life compared to older incandescent lamps and even CFL lamps.

The main concerns are the usual Suspects- Poor Power factor [PF] and Harmonic current generated by the lights. Below are some test results based on my experiments with these devices. I have tested following LED light fixtures:

-

38W Commercial LED Manufacturer 1 [LED1]

-

12W Residential LED- Manufacturer 2 [LED2]

-

5W Residential LED- Manufacturer 3 [LED3]

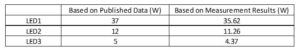

Power

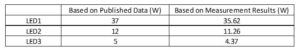

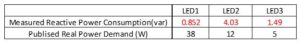

LED lights are supplied with standard 120V AC, 60Hz and the power consumed is compared with the data printed on the light fixture.

Measurement results indicate that the power consumed is close to the manufacturer spec for all fixtures.

Power Factor [PF]

Power Factor is the ratio of real power (W) to the apparent power (VA) flowing in the circuit. This is a dimensionless number and is usually expressed as a number between 0 and 1. Alternatively PF is the cosine of the angle between the current and voltage vector. A purely resistive load will have a zero phase angle between current and voltage and hence will have a PF of 1 or 100% (Cos 0 =1). Similarly, a purely capacitive load will have a leading PF of between 0 and +1. A purely inductive load will have a lagging PF of between 0 and 1. Majority of loads in any power system will have PF varying between 0.5 and 0.9

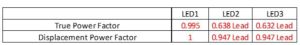

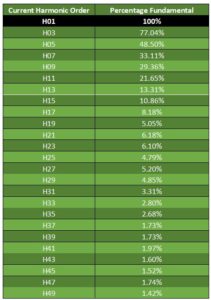

For harmonic producing loads two types of PF can be defined – True Power Factor and Displacement Power Factor. True Power Factor takes in to account contribution from both fundamental (50/50Hz) and harmonic frequencies. Displacement Power Factor is the power factor considering only the fundamental (50/60Hz). Switch mode devices such as LED lights may yield very good Displacement Power Factor (>95%), but usually has very low true power factor (50-60%).

The PF for all three LED lights were measured and the results are provided below.

It can be observed that the true PF for residential LED 2 &3 is bad at around 0.6lead, whereas the commercial LED has a good PF. This is due to the special PF correction circuitry built in to the commercial LED driver. These type of drivers also tend to me more expensive.

It is interesting to note that the residential LED1 & LED2 have a leading (i.e. capacitive PF). This means the LED lights are a net source of capacitive reactive power to the grid (though minuscule per lamp). It can be seen that if there are thousands of these lights, the capacitive reactive power injection (Vars) in to the grid could be worth taking a second look.

LED lights have a leading PF due to the presence of front end capacitors which includes filter/noise capacitors.

Harmonics

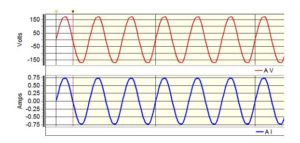

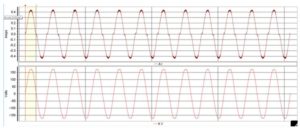

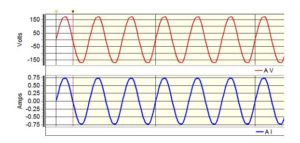

LED lights are non-linear devices in the sense that the current drawn from the supply does not follow the voltage. Current is drawn as short ‘bursts’ to charge the capacitor inside the LED driver. This can be clearly seen in the graph below wherein the capacitors draw currents at the peak of the voltage. Essentially the capacitors will only draw current if its voltage is lower than the supply voltage. As soon as the rising edge of the sine wave is greater than the capacitor voltage, the diode bridge becomes forward biased and a quick pulse of current is delivered to the capacitor. After the capacitor voltage becomes equal to the peak of the sine wave, there is not more charge delivered to the capacitor and the current quickly tapers off. This is the reason behind the triangular shaped current waveform seen. In fact, the very same current wave form is a characteristic of vast majority of switched mode power supplies (LED, CFL, Computer power supplies etc.)

This non-linear current is rich in harmonics that can cause additional heating the supply transformers, cables etc.

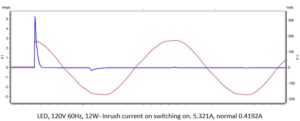

LED2, 120V 60Hz, 12W- Input voltage and the corresponding current waveform.

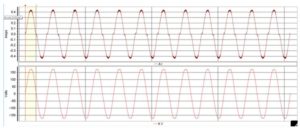

For comparison, current draw by a traditional incandescent lamp is shown below. The current essentially follows the voltage and hence it is a linear device (I follows V).

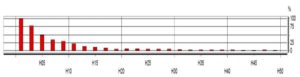

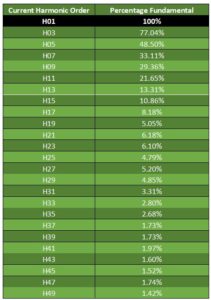

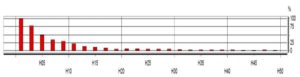

The spectrum of the harmonic current for 12W LED2 is shown below up to 50th harmonic order (i.e. up to 60Hz*50 = 3,000Hz) is shown below.

The current harmonic of the tested non-power factor corrected residential LEDs are dominated by 3rd, 5th, 7th, 9th 11th, 13th & 15th. Of these 3rd, 9th, 15th are called zero sequence harmonics. Zero sequence harmonics add linearly in the neutral conductor and can cause overloaded neutral.

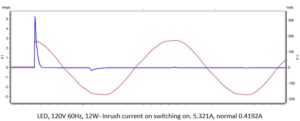

LED Light Switch ON Inrush Current

Due to the presence of front end DC bus capacitors, switching ON an LED light will result in a short and narrow current spike in the system. Below is one such graph shown for a 12W LED. As can be seen, the peak current surge is 5.3A whereas the normal running current peak is 0.4192A. This is 12.7 X the regular current peak. Switching on hundreds of lights through one circuit breaker or fuse could cause a trip of the breaker / fuse.

The inrush current itself is not a problem peculiar to LED lights. CFL lights, Computer power supplies and even regular incandescent lamps have some initial current inrush. Recognizing that this phenomenon exist will help in troubleshooting system malfunctions. The magnitude of the peak current depends on many factors and is not always a constant number. Variables include the point of the voltage waveform at which switching happens, short circuit capacity of the system and the size of the driver capacitor.

Observing the above waveform it is clear that switching ON and OFF the LED lights on a frequent basis cannot be good. Every time switch is closed, a high magnitude (relative to normal current) flows through the front end diode in to the capacitor. This will cause a temperature increase of the diode junction and if repeated frequently can damage the diode and hence the LED driver.

38W Commercial LED with Power Factor Correction

Below is the current waveform for the 38W commercial LED light. As can be observed, the driver has a built-in Power Factor Correction (PFC) circuitry. Notice that the current waveform closely follows the voltage.

For 38W commercial LED

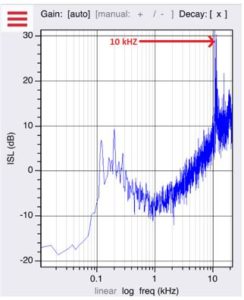

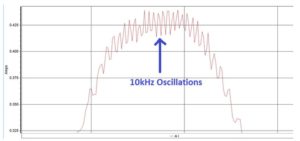

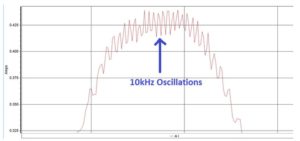

It is also observed that the current waveform is showing some noise at the positive and negative peaks. The current waveform is zoomed in and the details are shown below. There is a 10Kz oscillation riding on top of the current waveform. A hissing Nosie was also noticed when the LED light was turned ON.

HF noise on the peak of the current waveform-10KHz

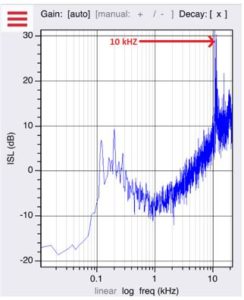

It was decided to see if the hissing noise heard and the noise on the current waveform has something to do with each other. An audio spectrum analysis was performed on the audible hissing sound from the LED and the spectrum is shown below. As can be observed, there is a strong 10kHz component in the audio. It can be concluded that the audible noise is due to the 10kHz noise riding on top of the current waveform. 10Khz is most likely the switching frequency of the internal circuitry of the driver circuit.

Audio Spectrum Analysis of LED driver noise. Note the peak noise at 10kHZ.

![]()

![]()